The world of security solutions keeps getting smarter and more linked up every day. Think about it: homes, businesses, and public spaces all need reliable ways to watch over things. The global electronic security market, valued at around $56.5 billion in 2025, is set to grow at about 8.45% each year, reaching roughly $150 billion by 2032. That’s a huge jump, driven by rising needs for better protection against theft, vandalism, and other risks.

However, jumping into this market isn’t simple. Starting from scratch means dealing with heavy costs for factories, figuring out tricky tech, and handling supply chains that stretch across countries. These hurdles can stop even the best ideas in their tracks. What if there was a smarter path? Teaming up with experienced original design manufacturers in security camera manufacturing lets you skip the headaches. For brands eyeing growth, OEM and ODM manufacturing offer a direct route to stand out. This approach not only saves money but also lets you pour energy into what matters most—building your brand and reaching customers.

Challenges of Building Your Own Production Line

Launching a security camera brand sounds exciting, but setting up your own factory brings real-world problems that can slow everything down. Many entrepreneurs dream of controlling every step, yet the reality hits hard with financial, skill, and timing issues. These barriers often lead to delays or outright failures, especially in a field like security camera manufacturing, where tech changes fast. Understanding these challenges helps see why partnering with pros in OEM and ODM service makes sense. It’s not just about avoiding pitfalls; it’s about moving ahead while others get stuck.

The High Barrier of Capital Investment

Pouring money into a production line isn’t cheap. You need land, buildings, machines for assembly, and testing gear—all adding up quickly. For instance, a basic setup for making security cameras might cost $5 million to $10 million upfront, based on reports from manufacturing plant setups. That’s before you even buy raw materials like lenses, sensors, and housings. Small brands or startups rarely have that kind of cash lying around. Loans help, but interest eats into profits later. And hidden costs creep in too, such as utilities for running injection molding machines or storage for parts.

In China, where many security camera manufacturing hubs sit, land prices in industrial parks have risen 15% in recent years, making it tougher for newcomers. Without deep pockets, this barrier keeps many ideas on paper. Instead of sinking funds here, smart brands turn to OEM and ODM manufacturing partners who already have the setup. They handle the heavy lifting, letting you focus on sales.

Besides the financial difficulties, another big issue arises when you lack the right people to make it all work. Building a team takes time and know-how, which not every brand has at the start.

The Shortage of Technical Expertise and Talent

Finding skilled workers for security camera manufacturing proves tough. You need engineers who understand circuit boards, software for smart features, and quality testers who spot flaws in night vision or wireless connections. In places like the U.S. or Europe, talent shortages in electronics mean salaries climb high—up to $100,000 a year for experienced pros. Training new hires adds months and costs, with no guarantee they’ll stick around. Technology evolves fast; today’s security camera might need updates for better encryption tomorrow. Without in-house experts, you risk products that lag behind competitors. Supply chain glitches, like chip shortages seen in 2021-2022, worsen this if your team can’t adapt. Many brands end up outsourcing bits, but that fragments control.

OEM and ODM service providers bring ready teams with years in the field. They know how to integrate features for wireless camera models, saving you the hunt for rare skills. Beyond skills, the clock ticks loudly in this industry. Delays can mean missing out on hot trends, pushing brands to seek faster ways forward.

Time Cost and Missing the Market Window

Time slips away when building from zero. Designing a production line, sourcing parts, and testing prototypes can take 12 to 18 months. During that stretch, market needs shift—maybe full color night vision becomes standard, or demand for OEM and ODM security cameras surges. If you’re late, competitors grab the sales. Regulatory hurdles add more wait time; getting certifications like CE or FCC for export markets involves inspections and paperwork. In security camera manufacturing, where seasons affect buys (like holiday spikes), missing a window hurts revenue.

One study showed startups lose 20% potential market share for every three-month delay. OEM and ODM manufacturing cuts this down, with partners like Jortan delivering from sketch to shelf in weeks, not years. Their established lines mean you launch powerful security camera variants right when buyers want them.

OEM and ODM Models as the Key Solution

Facing those tough challenges, many turn to proven models that streamline the path to market. OEM and ODM stand out as smart choices for brands in security camera manufacturing. These partnerships shift the burden of production, letting you innovate without the grind. They fit perfectly for the growing demand in connected devices, where speed wins. By understanding these models, you see how they solve real problems and open doors.

What Are OEM and ODM?

OEM, or Original Equipment Manufacturing, means a maker builds products to your specs, which you sell under your name. ODM, Original Design Manufacturing, goes further—they design and build, often tweaking existing templates for your needs. In security camera manufacturing, this covers everything from basic wireless models to advanced smart ones. For example, Jortan offers OEM and ODM service, handling your camera builds with custom logos or apps. About the difference, OEM suits if you have designs ready; ODM helps if you’re starting fresh. Both cut costs by using the partner’s factories, like Jortan’s 30,000m2 plant in China.

Over 70% of electronics brands use these models for faster entry, per industry insights. They make sense for OEM and ODM security cameras, ensuring products meet global standards without you building from scratch. With basics clear, the real pull comes from what these models deliver in practice. Savings and support make them game-changers for brands.

Core Advantages of the Partnership Model

Production speed has also increased significantly. For example, at Jortan, the lead time for mass OEM and ODM manufacturing can be as short as 7-15 days. Through mature processes, cameras undergo multiple inspections, ensuring consistently high product quality. Flexibility is also a key benefit: you can customize the color, features, or packaging of your cameras. Risk is also reduced because our partners manage the supply chain, even in the face of global supply chain disruptions. In short, these advantages allow brands to focus on marketing rather than worrying about manufacturing issues.

Once you are attracted by these advantages, the next step is to understand how the entire process works. From concept to finished product, working with the right partner will make the entire process smooth and seamless.

Collaborative Process from Sketch to Finished Product

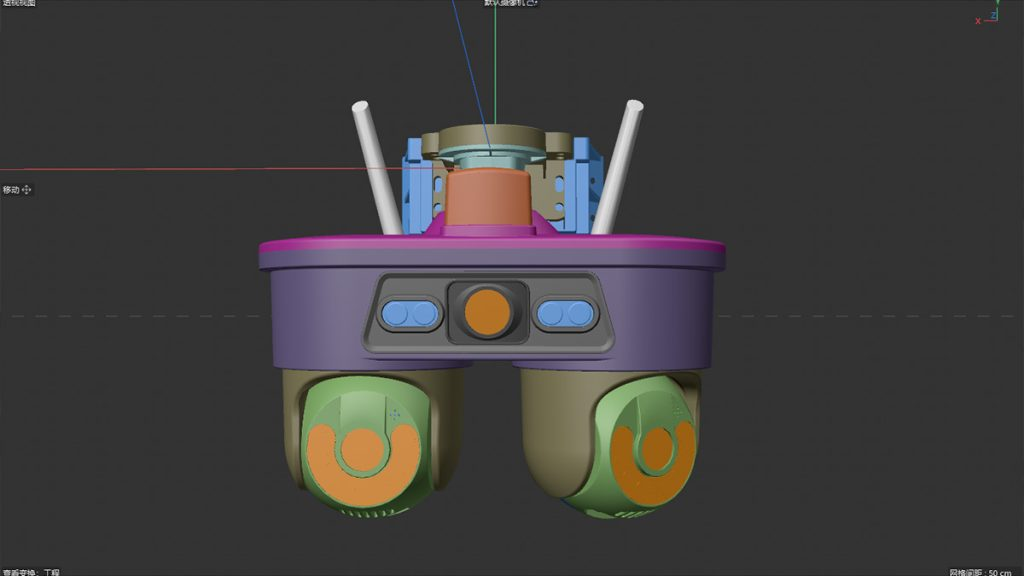

It all starts with your idea. Simply share your specifications, and the manufacturer will leverage its R&D capabilities to optimize the design. For example, Jortan handles mold making, injection molding, chip processing, assembly, and quality testing (twice). Prototypes are typically completed quickly within a few weeks for your feedback. Production is then scaled up within their integrated production chain. The product packaging will feature your brand identity, and then it’s ready for shipment. This end-to-end process for OEM and ODM security cameras ensures a smooth product launch, minimizing any potential issues. Regular updates keep you informed of the latest progress, building trust along the way.

Maximize Your Brand Value in the Cooperation

Knowing the process is one thing; making the most of it takes strategy. In OEM and ODM manufacturing, success hinges on how you engage. Brands that dive deep reap bigger rewards, turning partnerships into growth engines. This section digs into ways to amp up your edge in security camera manufacturing.

Communicate Deeply and Define Your Requirements

Clear talks set the tone. Spell out needs early—what features for your wireless camera? Specs like resolution (1080p or higher) or battery life matter. Use drawings or samples to avoid mix-ups. Jortan’s team, with over a decade in the field, listens and suggests tweaks. Regular calls or visits build rapport. Define timelines too; aim for 1-3 day samples. This precision ensures OEM and ODM service matches your vision, boosting brand loyalty.

Communication opens doors to expertise. Tapping into the maker’s skills elevates your products beyond basics.

Leverage the Manufacturer’s Engineering & Design Expertise

Original design manufacturers like Jortan bring engineering teams for innovations in full color smart camera technology, such as better night vision or app integration. They suggest materials that cut costs by 10-20% without skimping on quality. Collaborate on designs; their experience in security camera manufacturing spots issues early. Expertise means nothing without safeguards. Protecting your ideas and ensuring top-notch output keeps the partnership strong.

Ensure Quality Control and Intellectual Property Protection

Quality checks are non-negotiable. Insist on systems like ISO standards or full inspections—Jortan does raw material tests and double finished checks. For IP, sign NDAs and use contracts that lock in your designs. In OEM and ODM manufacturing, this prevents leaks. Audits help; visit factories to see processes. With certifications like their innovative enterprise status, partners build trust. Solid QC means fewer returns, strengthening your brand.

A Checklist for Selecting Your Ideal Manufacturing Partner

Maximizing value starts with picking the right ally. Not all OEM and ODM services fit every brand. Use a checklist to vet options in security camera manufacturing. Focus on key traits that match your goals.

- Production Capacity and Vertical Integration: Check if they can handle your volume. Jortan’s 30,000 sqm factory with 450 workers scales for big orders. Vertical integration—controlling from parts to packing—speeds things, reducing delays by 20%.

- Technical R&D and Customization Flexibility: Look for R&D depth. Jortan plans expansions in 2026 for more assembly lines and machines. Flexibility means easy tweaks for Jortan wireless camera models. Test with small runs; good ones offer mold opening and app customization for OEM and ODM security cameras. Experience counts—over 10 years means they handle trends like AI integration.

- Quality Systems and Compliance Certifications: Prioritize certified makers. Seek ISO 9001 or product-specific like FCC for exports. Jortan’s rigorous tests and innovative status highlight reliability. Compliance ensures your security camera meets global rules, avoiding recalls.

Conclusion

In today’s fast-paced security market, getting ahead means smart moves. OEM and ODM manufacturing isn’t just outsourcing—it’s a way to channel energy into branding and sales while pros handle the make. Brands thrive by focusing on strengths, not factory woes. Partnering with Jortan gives access to our 12+ years in security camera manufacturing, full production from molds to assembly, and strict quality steps. If you have any customization needs, please contact us at kingjin@safejortan.com.cn, and we will provide you with guidance. Trust us, this path will accelerate your brand development and transform your creative ideas into market success.